Home-Products-Plastic granulation unit > Internal mixing single screw granulator

Home-Products-Plastic granulation unit > Internal mixing single screw granulator

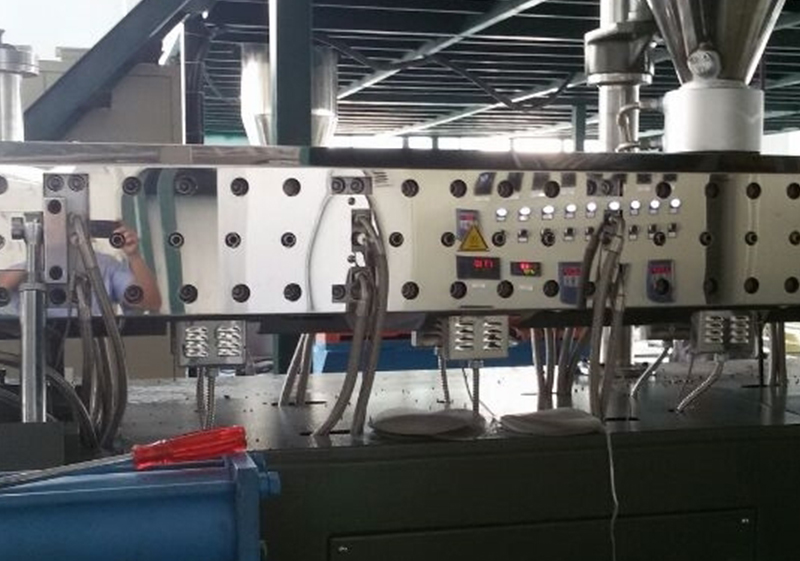

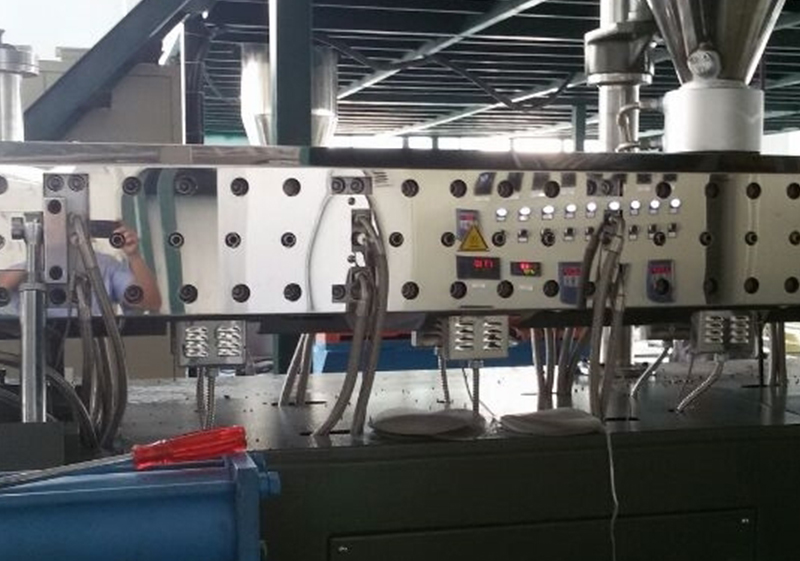

Description:The internal mixing single screw granulator is a unit designed for the production of plastic sheet extruders. The elevator is automatically interlocked with the internal mixing machine, and adopts an automatic feeding function. When pouring, it can automatically delay and return to its original position. It does not require special operating techniques and can produce high-quality products with excellent safety. Accurate temperature control reduces damage and waste of raw materials.

Nature

ManufacturerUpdateTime

2023-12-8Visits

2546Products

PRODUCT CATEGORYFilling masterbatch granulation unit

Rubber masterbatch granulation unit

Related articles

The internal mixing single screw granulator is a unit designed for the production of plastic sheet extruders. The elevator is automatically interlocked with the internal mixing machine, and adopts an automatic feeding function. When pouring, it can automatically delay and return to its original position. It does not require special operating techniques and can produce high-quality products with excellent safety. Accurate temperature control reduces damage and waste of raw materials.

Precautions for no-load trial operation:

1. Firstly, start the lubrication oil pumps and hydraulic stations of the mixer and check if the oil supply to each part is normal. After 15 minutes of normal operation of the oil pump and hydraulic station, start the main motor and observe whether the rotor direction is correct from the outlet end of the mixing chamber. Usually, before leaving the factory, the mixer is operated by air for more than 2 hours and by idle operation at the user's location for more than 4 hours.

2. Open the cooling water system of the mixer and check for leaks.

3. In both manual and automatic operation modes, the weight, feeding door, and unloading door should be opened multiple times, and the action should be flexible and reliable.

4. During the empty running test of the mixer, check the following items:

a. The lubrication of various lubrication points such as the reducer transmission gear and bearings is sufficient, and the sealing parts are well sealed.

b. There should be no significant vibration or periodic noise during operation.

c. When idling, the main motor is at a single speed, and its power consumption should be less than 15% of the rated power. There should be no sudden temperature rise in the bearings of various parts of the mixer, and the temperature rise of the rotor bearings and reducer bearings should be ≤ 20 ℃.

The thickness control of the plate in the internal mixing single screw granulator adopts screw adjustment and hydraulic pressure wheel bi-directional adjustment to control the thickness of the plate. The straight diameter of the pressure roller is 350mm, and a dual circuit cooling system is used in conjunction with a mold temperature control machine to control the temperature of the pressure roller to ensure uniform thickness of the sheet metal.